Solutions & Services

We will help you get the most out of your production and of your equipment

Product Groups

We provide solutions in the following areas.

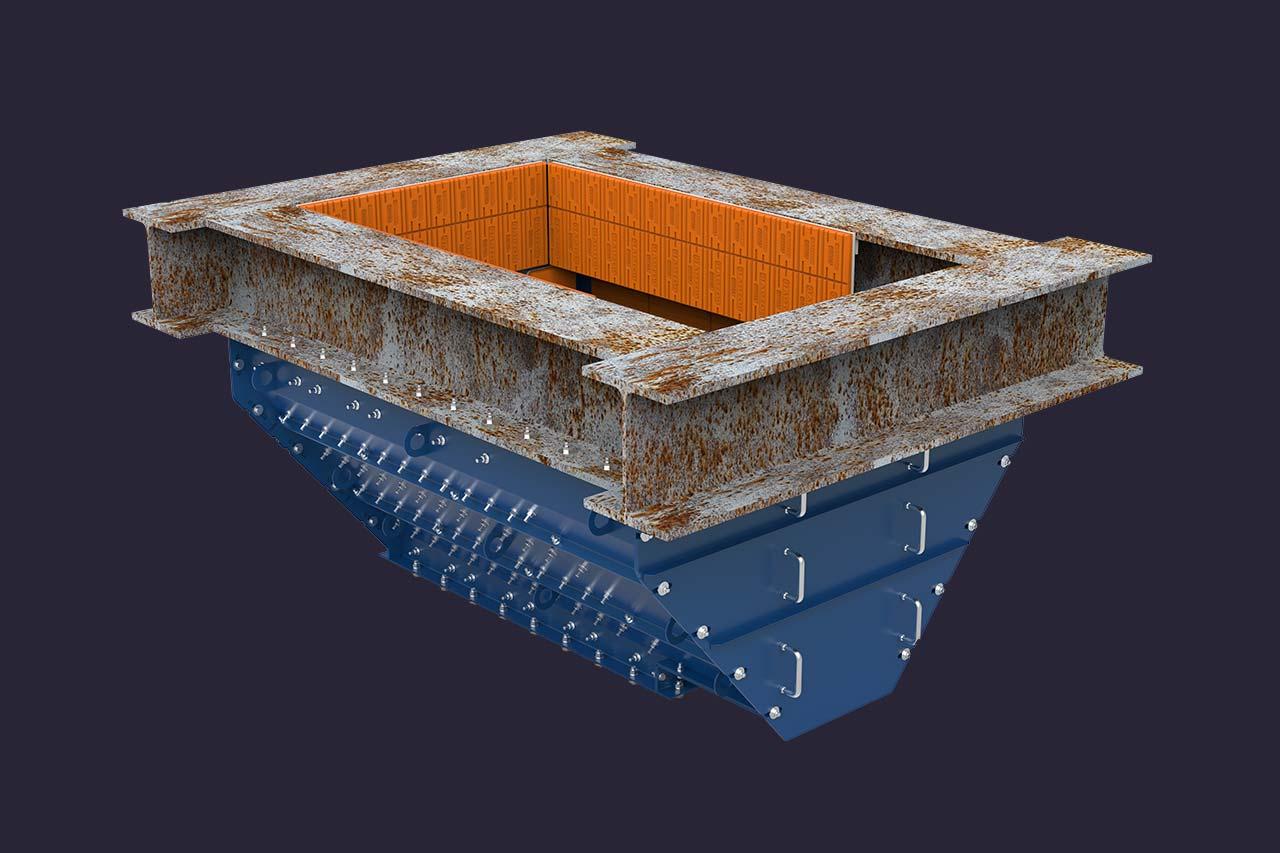

Steel Structures

We design and manufacture different kinds of steel structures such as platorms, shelters, profile frame containers, chutes, silos etc…for a variety of applications.

Subcontracting

We do manufacture machines, equipment and structures based on the customer drawings. But, we prefer that you just provide us the spec a 3D model or some sketches and we pick it up from there. If safety, easy installation, maintainability and availability is of interest…we are the right ones to talk to. Whether it is different types of conveyors, lifters, chutes, steel structure or other medium sized structures, let’s discuss.

Our production facility consists of 3000 m2 production area with 3x 10 t lifting capacity makes it possible to build also a bit larger structures. Our wide range of cooperation partners and subsuppliers in Finland and abroad means we don’t normally run out of capacity.

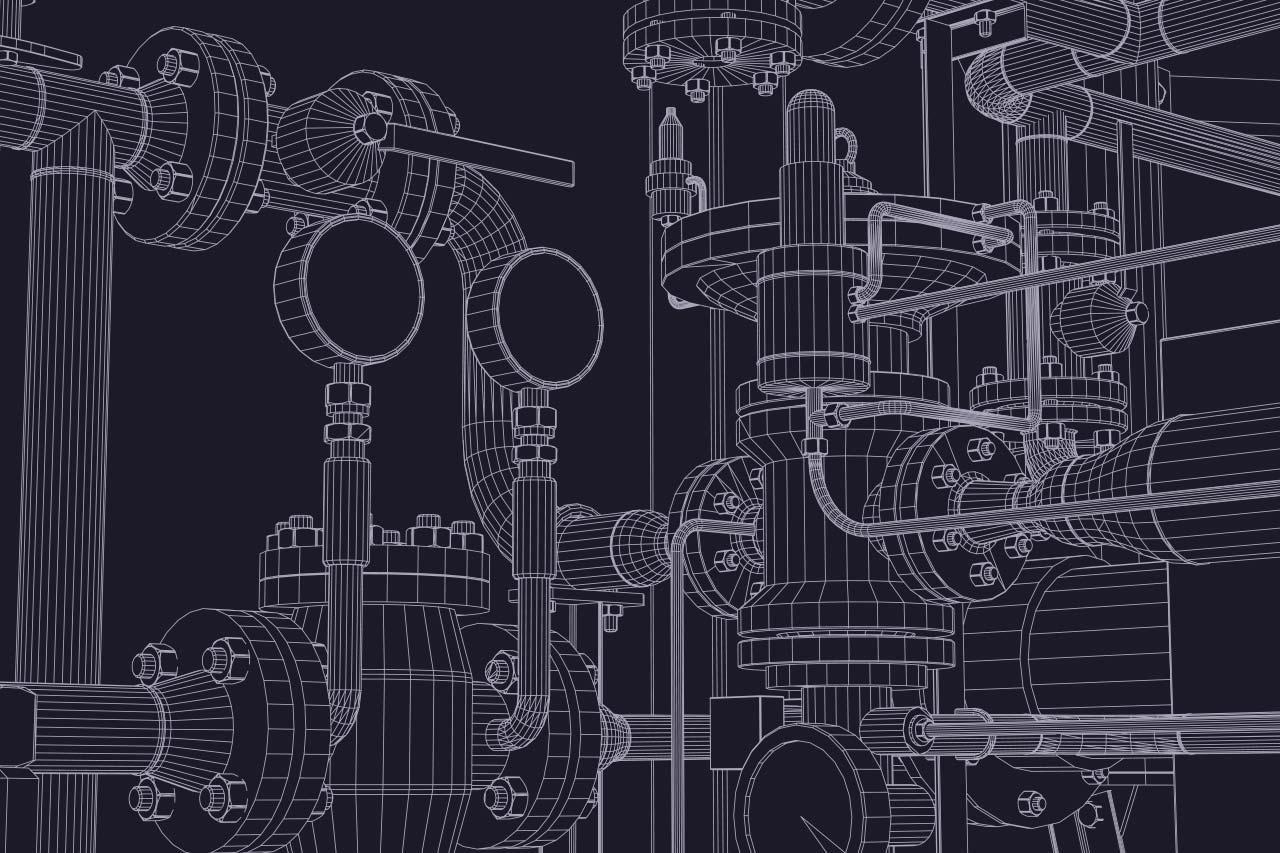

Design

Our practical engineering team aims to design simple structures that are easy to manufacture accurately, but solutions that the installation and maintenance teams will know to appreciate. The installation locations often have their limitations with regards to transfers routes, lifting equipment etc. To avoid unpleasant surprised we are glad to come by and check the routes, lifting possibilities and to add the necessary lifting points or to design the equipment in suitable size elements. The small things like a bit larger maintenance hatches don’t really cost anything to manufacture, but over the lifetime can cause quite a bit of cost and pain.

We basically design anything, do the strength calculations, make the models, workshop drawings, material lists and documentation. And we do not fall in love with them, but share them happily to our customers and their maintenance organizations.

Conveyors and Modernizations

We do optimize each conveyor to it’s application so that the wear plates can be inspected and changes, the rollers can be quickly replaced also below the skirtboard sealing and the safety shields are easily removable.

Every project, especially the installations generate always a few new ideas how we could make the solutions smarter, easier to install and more simple to use. The overall solution is one that will help to improve the availability of the production process and to minimize the operating expenses.

Surveys, Inspections & Calculation

Our engineers will come to you, will be there during the installation and moderinsation. This gives a good foundation for the ideas, calculations and proposals for solutions that consider the conditions at site and help you make the most out of your production..

Decontamination Containers

The decontamination containers help in ensuring this target. When using disposable overalls, these can be removed either outside or on the dirty side, before washing the boots, hands and vacuum cleaning the clothes. Entrance to the clean side goes through an air shower, where high speed – low pressure air is used to detach dust from the clothes.

On the clean side it is time to remove the personal protection gear, clean it up once more and leave to the clean areas.

Water Fog

One way of preventing dust from spreading to the surroundings is the use of very fine water fog. When the droplets are so small that they don’t freeze in the winter air, but still catch the dust particles and drop them down. With droplet size below 0,1 mm, the amount of water used for example in a transfer point is less than 100 l/h, which is insignificant in comparison to the mass flow of material.

The fog can be used on transfer points, discharge ends, door opening, hoppers … you name it, we do it.

Wear Protection

Hitting high and hard is always a beautiful way to load and discharge, but when considering wear, tear and dusting, it’s the opposite. By engineering the chute geometry correctly, wearing can be reduced to a great extent. If the material does not touch the walls, the wall will not wear and yes, you can actually calculate or simulate the material flow.

Benefits

Our solutions provide you several advantages.

Occupational safety

Solutions meeting today’s safety requirements.

Easy to Maintain

Fast and maintenance friendly structures.

Optimization

Functionality and maintenance intervals considered.

Durability

Wear minimization through well thought out engineering.